Details, Fiction and machining

Add your sections, pick out amount, content and complete to receive a free of charge quote inside the future 24 hrs.

Drilling is used to make a round hole. It truly is attained by a rotating Software that normally has two or four helical cutting edges. The tool is fed in a very path parallel to its axis of rotation into the workpiece to kind the spherical gap.

The key motion is furnished by rotating the workpiece, along with the feed movement is reached by relocating the cutting Resource slowly and gradually in the course parallel towards the axis of rotation in the workpiece.

5 Essential Elements For precision machining

Milling operations are functions through which the slicing tool rotates to deliver reducing edges to bear from the workpiece. Milling machines are definitely the principal equipment Device used in milling.

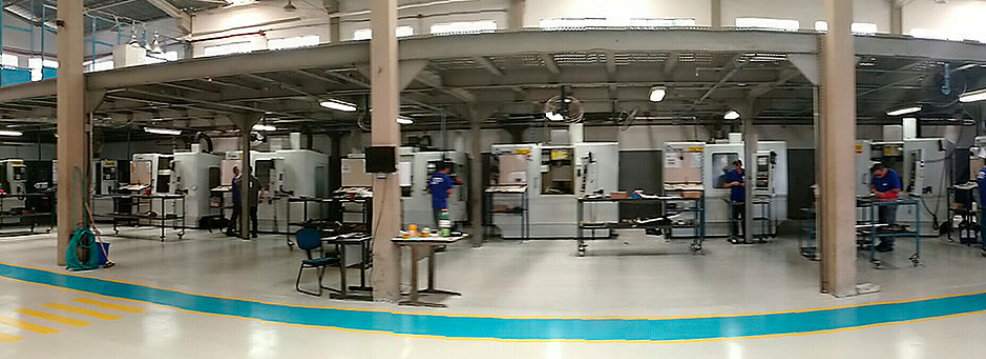

Machining Machining (through the equipment Instrument and reducing Software) shapes metallic workpieces. Comprehending both equally regular and advanced machining tactics is important to conquering the various dimensional and end issues associated with mould machining.

A typical bed has X and Y journey, which is in between 3 and four ft square by using a rotary table or a larger rectangle with out a desk. The pendant generally delivers involving 4 and 8 feet of vertical movement. Some mills have a significant (thirty" or even more) integral going through head. Proper angle rotary tables and vertical milling attachments are offered for more adaptability.

What on earth is precision resistor? A precision resistor is actually a resistor which has an true price that is rather near (or exact) to its nominal (or mentioned price). Thus, precision resistors have an exceedingly diploma of accuracy of getting extremely near for their nominal values.

Using the modern proliferation of additive producing technologies, regular machining has been usinagem de precisão retronymously categorised, in considered and language, for a subtractive producing technique. In slim contexts, additive and subtractive techniques might contend with each other.

Fascination About machining

Specialised etching tools then uses acid to selectively get rid of any substance remaining unprotected via the mask, exactly cutting all of the features of the aspect. The mask is then stripped from your metal, leading to a burr cost-free sheet of precision areas. Elcon’s limited system controls offer the opportunity to reach a tolerance as restricted as +/-.0002†on some parts.

Precision machining is often a procedure in which substance is removed from a element to an exceedingly higher tolerance. The tolerance held relies on the device but most percision CNC equipment is not going to have a problem Keeping a tolerance of 0.

Only one stage Instrument has a person leading edge and is particularly employed for turning, dull and planing. Throughout machining, the point of the tool penetrates beneath the original function floor of your workpart. The purpose is usually rounded to a specific radius, known as the nose radius.

A milling device is commonly termed a mill by machinists. The archaic term miller was typically Utilized in the 19th and early 20th hundreds of years.[7]

5 Simple Techniques For machining

Tlusty discovered that there's a "sweet spot" in machining that is located when there is the correct correlation Along with the depth of cut, spindle pace, Resource geometry, etc.